Many times we find that the appearance of some self-adhesive labels is not so neat, which may affect our perception, such as the edge of the self-adhesive label is not smooth, etc., so what are the reasons for this situation?

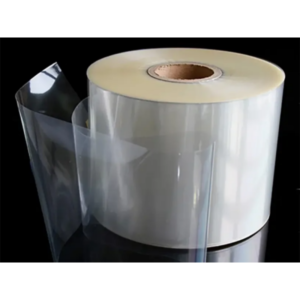

First of all, check whether there are burrs on the self-adhesive material. The edge of the roller self-adhesive material is smooth and undamaged, which is the basis for ensuring the printing quality of the self-adhesive label.

Secondly, when the self-adhesive material is divided, if the cutting tool is unreasonably adjusted or the blade is not sharp enough, or if there is a crack in the white cotton paper or the end of the paper in the self-adhesive material, the crack may be continuous or random. Yes, it is possible that the self-adhesive material in the drum is on one side of the drum or on both sides. Therefore, for the adhesive raw materials in the previous printing equipment, carefully check whether there is a small gap between the glossy paper and white cotton paper. It is also the cause of cracks on the edge of the self-adhesive material.

The last is to check whether the separation port of the roll sticker material is vertical and whether the rewinding is tight or loose. If the separation port of the roll sticker material is uneven, it will not only affect the registration after printing, but also cause problems due to film cutting. It is difficult to discharge waste due to changes in the position; inconsistent tightness and looseness during rewinding will often cause changes in the paper type force during printing, and uneven support force will also lead to quality problems in printed products.