Adhesive labels may peel off, curl at the edges, or have blurred text when exposed to water. Below are handling methods and preventive suggestions for different scenarios.

I. Handling Methods for Water-Exposed Adhesive Labels

- Re-adhesion: If the label is only slightly damp, try drying it with a hair dryer on the hot air setting and reapply it. Note that high-adhesion glue should be used to enhance stickiness.

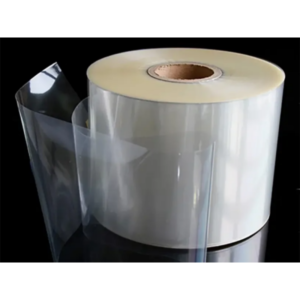

- Label Replacement: If the label is severely wrinkled or peeled off, replace it with a water-resistant adhesive label made of materials like PP synthetic paper, PET, or PVC. These materials have excellent water and oil resistance, making them suitable for humid environments.

II. Preventive Measures for Adhesive Labels

- Prioritize water-resistant adhesive labels: For labels that are in long-term contact with water or in humid environments, it is recommended to use water-resistant adhesive labels directly. These labels achieve long-lasting water resistance through a special coating and high-adhesion glue, and can also resist oil stains and scratches.

- Avoid long-term soaking: Non-water-resistant labels should be kept away from water. If temporary contact with water is unavoidable, use a waterproof bag or cover them with a protective layer to prevent water from seeping in and affecting stickiness.

III. Special Scenario Recommendations

- Food Packaging: Use water-resistant labels that meet food safety standards to ensure they are non-toxic, harmless, and have long-lasting stickiness.

- Outdoor Signage: Prioritize water-resistant labels with UV resistance to prevent fading or peeling caused by long-term exposure to sunlight and rain.