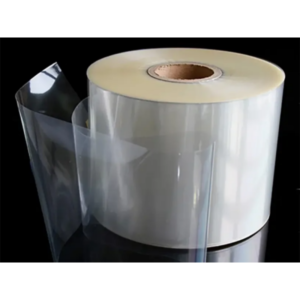

Speaking of barcode printing, it is necessary to mention the two mainstream technologies currently: thermal printing and thermal transfer printing. Among them, thermal printing is more familiar to the general public. The paper receipts given when shopping at supermarkets or buying lottery tickets are mostly printed with thermal printers. These printers are small and simple, but the print quality is poor, lacking scratch resistance and having a short storage time. With the development of thermal transfer technology and the advancement of thermal transfer printers in terms of miniaturization, portability, high-speed continuous printing, and printing in harsh environments, thermal transfer printing has entered a new stage of development and has become an absolute mainstream in the field of barcode printing. The advantages of thermal transfer printing lie in its ability to produce barcodes patterns that are resistant to high temperatures, stains, heat, friction, corrosion etc., through the use of a carbon ribbon for transferring ink onto various media such as paper, plastic film,and metal achieving high-definition prints. It can also adapt to harsh industrial printing environments with high character quality and long service life meeting requirements for continuous long-term industrial-grade prints.