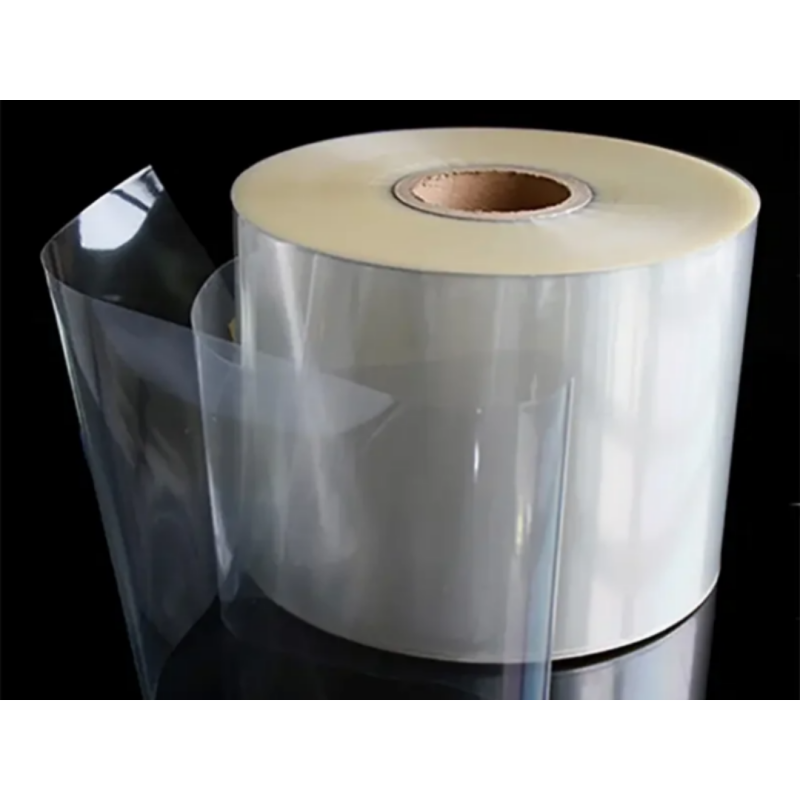

From snack packaging bags on supermarket shelves to core battery components of new energy vehicles, from label stickers on daily chemical products to insulating materials for high-end electronic devices, Biaxially Oriented Polypropylene Film (BOPP Film), with its thin yet tough characteristics, has become an “invisible cornerstone” spanning consumer goods and high-end manufacturing. This polypropylene film processed by special techniques, relying on the comprehensive advantages of safety, toughness, easy processability, and excellent cost performance, constantly breaks through application boundaries, exerts unique value in multiple fields, and becomes an indispensable key material in modern industry and daily life.

I. Consumer Goods Field: Building a Solid Defense for Packaging Safety and Quality

In consumer scenarios such as food and daily chemicals, BOPP Film has become one of the preferred materials in the packaging field due to its triple advantages of “safety + practicality + aesthetics”, and its application is highly consistent with industry standards and consumer needs. In the food packaging field, acrylic-coated BOPP Film stands out with strict safety indicators, complying with the national standard GB/T 26690—2011. It adopts food-grade raw materials and acrylic coatings, with a total migration volume of ≤10 mg/dm² and heavy metal content of ≤1.0 mg/kg, eliminating the migration of harmful substances from the source and adapting to the packaging needs of various foods such as snacks, pastries, coffee, and milk powder.

Targeting the characteristics of different foods, BOPP Film has derived diversified application solutions: ordinary transparent BOPP Film, with a transparency of ≥90% and glossiness of ≥80%, clearly displays the shape of food and enhances shelf appeal; aluminum-plated composite BOPP Film can block oxygen and ultraviolet rays, and combined with extremely low water vapor transmission rate, extends the shelf life of dry foods such as potato chips and biscuits to 6-12 months, firmly locking in flavor and moisture; pearlescent BOPP Film, with its unique pearlescent luster, endows high-end positioning to chocolates, high-end pastries and other products, while meeting the requirements of heat sealability and moisture resistance. In the daily chemical field, water-proof, oil-proof, tough and tear-resistant BOPP Film is widely used in the outer packaging of shampoos, laundry detergents and other products. BOPP Film for self-adhesive labels, after corona treatment, has clear printing effect, can withstand daily friction and humid environment, and maintains label integrity for a long time.

II. High-End Manufacturing Field: Breaking Technical Bottlenecks to Empower Industrial Upgrading

With industrial upgrading and technological iteration, BOPP Film has gradually extended from basic packaging materials to core materials for high-end manufacturing, breaking foreign monopolies in fields such as new energy and electronic information, and becoming an important force for domestic substitution. In the new energy battery field, BOPP Film has reshaped the separator market pattern as a dark horse. Compared with traditional PE and PP materials, its longitudinal tensile strength is ≥200MPa and transverse tensile strength is ≥150MPa, with stronger puncture resistance, which can effectively resist internal expansion stress during battery charging and discharging and avoid the risk of pole piece puncture. At the same time, BOPP Film has uniform pore size (0.1-1μm) and porosity of 40%-60%, which can build efficient ion conduction channels. Moreover, it is resistant to electrolyte corrosion and has a heat distortion temperature of ≥120℃, with significantly improved safety margin, widely adapting to scenarios such as new energy vehicle power batteries and energy storage batteries.

More notably, recycled BOPP materials have achieved high-value reuse through modification. When blended with PP and PE substrates, they can increase the tensile strength of composite materials by 20%-30% and puncture resistance by 15%-25%, which are used in battery casings, spacers and other components. This not only reduces raw material costs by 30%-40%, but also saves about 1.8 tons of crude oil for every ton of recycled materials used, achieving a win-win situation of environmental protection and benefits. In the electronic information field, special BOPP capacitor film, with excellent insulation performance, has become a key material for MLCC (Multi-Layer Ceramic Capacitors), 5G communication base stations and new energy vehicle electronic systems. In 2025, Zhonglun New Materials launched the Changsu High-Functional Capacitor Film, filling the gap of domestic high-end new energy-specific capacitor film and helping electronic components develop towards miniaturization and high performance.

III. Special Scenario Field: Customized Solutions for Diverse Needs

Targeting the personalized needs of special scenarios such as tobacco, medical care and construction, BOPP Film has formed exclusive solutions through process optimization and functional modification, balancing practicality and safety. In the tobacco packaging field, ordinary BOPP tobacco film with a thickness of 20μm and 22μm has excellent heat sealability and dimensional stability. Shrinkable tobacco film can closely fit cigarette packs after heat shrinkage, with moisture-proof, anti-counterfeiting and fresh-keeping functions; high-gloss transfer base film and laser base film create a strong visual impact through special embossing and aluminum plating processes, while improving the anti-counterfeiting level of packaging and eliminating counterfeit products.

In the medical and health field, BOPP Film that meets food-grade safety standards can be used for pharmaceutical outer packaging and disposable medical supplies packaging. Its non-toxic, odorless and chemical corrosion-resistant characteristics can effectively protect the cleanliness of pharmaceuticals and medical supplies and avoid secondary pollution. In the construction field, BOPP Film can be used as the reinforcement layer and isolation layer of waterproof coiled materials. With wear resistance and ultraviolet resistance, it improves the service life and structural stability of waterproof coiled materials, adapting to the waterproof needs of various construction scenarios.

IV. Application Trends: Greenization and High-Endization Lead the Future Track

Currently, the expansion of BOPP Film’s application scenarios always advances around two major directions: greenization and high-endization. In terms of greenization, in addition to recycled material modification technology, the research and development of new products such as bio-based BOPP Film and fully degradable BOPP Film is accelerating. Measures such as film thickness reduction and production process optimization continuously reduce unit energy consumption and carbon emissions, in line with the “dual carbon” policy and circular economy trends. In terms of high-endization, domestic enterprises have stepped up capacity layout, promoting BOPP Film to develop towards thinner, stronger and more precise directions through the combination of introducing international advanced production lines and independent research and development. For example, after the commissioning of wide-width production lines, optical-grade BOPP Film suitable for high-end fields such as semiconductors and AR/VR can be mass-produced, further expanding the space for domestic substitution.

From consumer goods to high-end manufacturing, from basic applications to special scenarios, BOPP Film adapts to the needs of the entire industrial chain with diversified characteristics, not only undertaking the basic functions of daily packaging, but also helping high-end industries break through technical bottlenecks. In the future, with the rapid development of new energy, electronic information and other industries, as well as the continuous improvement of environmental protection requirements, BOPP Film will continue to iterate and innovate, develop new application scenarios in more segments, and support high-quality industrial development with “the power of thin materials”.