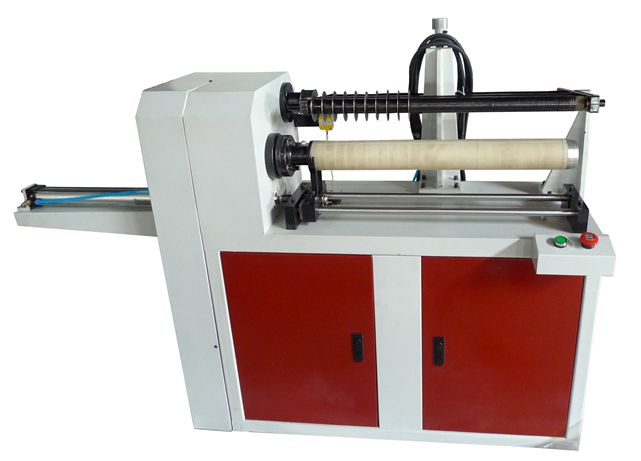

Equipped with dual-control technology of photoelectric sensing positioning and servo motor, the cutting length error can be stably controlled within 0.1mm, completely solving the pain points of “large dimensional deviation and inconsistent batches” in manual cutting. Whether it is the insulating tube core requiring a perfect fit in the electronics industry or the paper tube that accurately matches the width of the coil in the printing industry, it can achieve “one cut to precision”, directly reducing the scrap rate caused by unqualified dimensions by more than 15%.

The fully automated feeding-cutting-discharging process enables 24-hour continuous production without manual supervision. A single device can process more than 5,000 tube cores per day, and the efficiency is more than 10 times that of traditional manual cutting. Equipped with wear-resistant alloy tools and a stable transmission system, the equipment failure rate is less than 3%, reducing downtime for maintenance by more than 200 hours per year, helping enterprises break through production capacity bottlenecks.

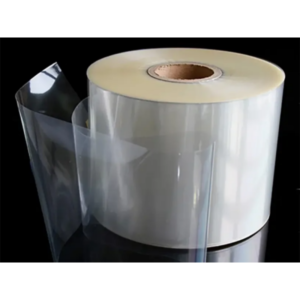

It supports cutting 6 categories of tube cores such as paper, plastic, and metal, and the specifications of diameter 5mm-200mm and length 10mm-1500mm can be adjusted freely. Only by replacing special tools (5-minute quick tool change) and adjusting touch screen parameters can the production scenario be switched, without the need to purchase separate equipment for tube cores of different specifications, helping enterprises save more than 30% of equipment procurement costs.

Equipped with triple safety protection (emergency stop button + photoelectric hand guard + fully enclosed protective cover), it meets ISO safety standards and eliminates potential safety hazards in cutting operations from the source. The 10.1-inch color touch screen is matched with a visual operation interface, and 30 sets of commonly used parameter templates are built-in. New employees can operate independently after 1 hour of training, greatly reducing the enterprise’s labor training costs.

Equipped with a PLC intelligent control system, it can real-time monitor cutting speed, tool life, and energy consumption data, support cloud data export and fault early warning, and realize “preventive maintenance” of equipment. Using an energy-saving motor (power 20% lower than traditional models) and a waste recycling device, each device can save more than 3,000 yuan in electricity bills per year, while reducing 15% of cutting waste, meeting the requirements of green production.