Among many plastic materials, PET (polyethylene terephthalate) and PVC (polyvinyl chloride) are widely concerned because of their unique properties. As a label material, PET labels and PVC labels have their own characteristics and are the two mainstream choices in the industry.

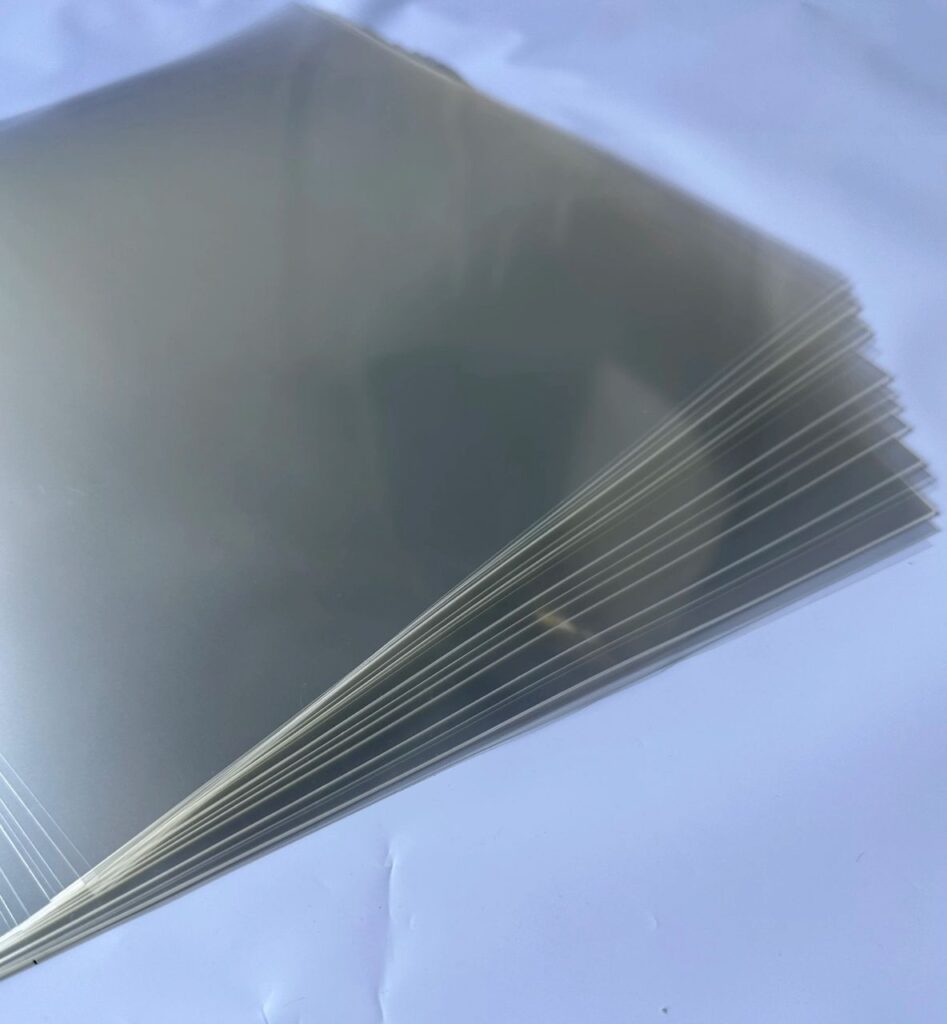

PET tags with its excellent resistance to heating, physical stability and environmental protection features stand out. It not only has good tensile resistance and wear resistance, but also maintains size stability in high temperature environments, which is suitable for electronics, automotive logos and other fields. The chemical resistance of PET labels is also a highlight, which makes them widely used in chemical labels.

In contrast, PVC labels have better flexibility, strong plasticity, and are more suitable for applications that require bending or fitting on irregular surfaces, such as cable labels and flexible packaging. However, the environmental protection of PVC materials has been a controversial point, which releases harmful substances when burned, so environmental impact should be considered when choosing to use.

In general, PET and PVC labels have their own advantages, and companies need to consider the use of the environment, product characteristics and environmental requirements when selecting materials to find the most suitable solution for their labels.